Why use drawing review checklists?

Good engineering drawings employ a variety of common elements in order to communicate design intent with clarity and conciseness. This variety can sometimes cause engineering drawing reviews to be difficult without a structured review process. It's easy to overlook things if you aren’t careful. Since much of what is included in a great part drawing for manufacturing should be similar across drawings, we’ve developed a free checklist for reviewing your part drawings.

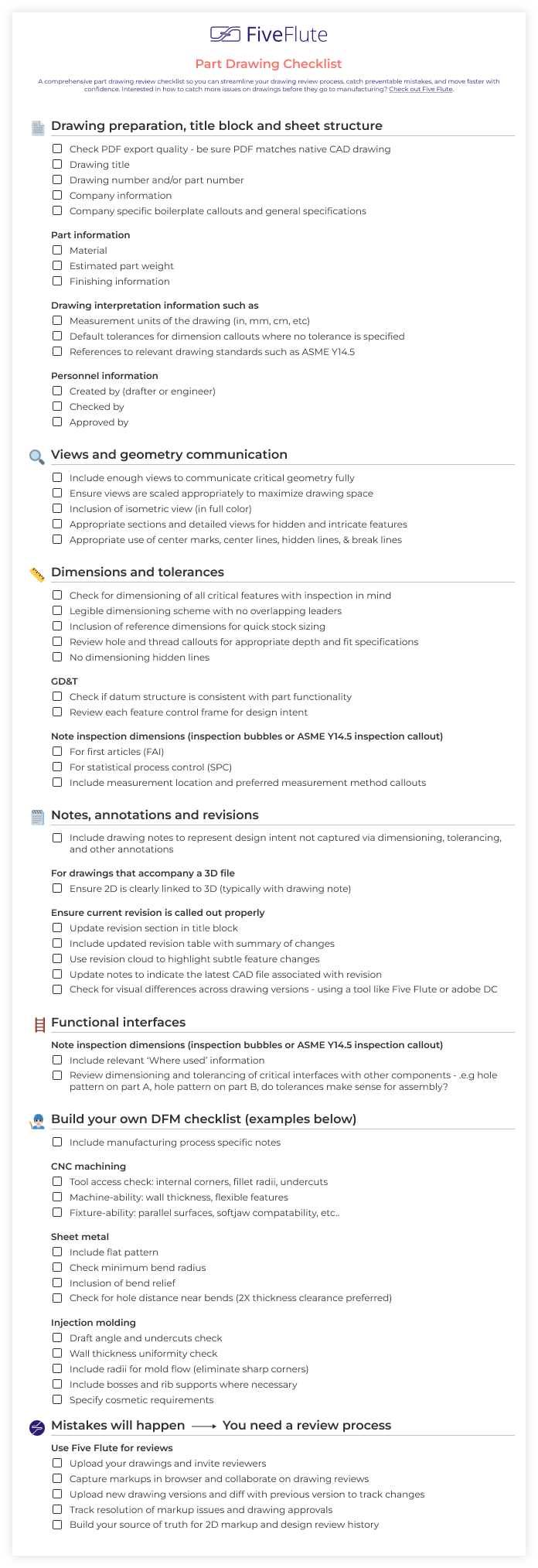

What’s included in the checklist?

We’ve broken down the checklist into 6 key areas, that cover all of the foundations from our Drawings 101 engineering guide. Here’s an overview of what’s included.

- Drawing preparation, title block and sheet structure. In this section we cover the basic checks for part and personnel information as well as checking that anyone with the drawing has enough information to interpret it correctly.

- Views and geometry communication. In this section we add checks for completeness of drawing views, as well as clarity and legibility of each view.

- Dimensions and tolerances. You can’t have a great drawing without accurate dimensions and tolerances. This section of the checklist ensures both completeness and accuracy of critical dimensions and tolerances along with some helpful checks for part inspection.

- Notes, annotations and revisions. Drawings are much more than just dimensions and tolerances. This section ensures you capture design intent properly and thoroughly with additional drawing annotations, functional manufacturing notes, and a thorough double check of part and drawing revisions to keep you in sync with your manufacturer about the latest version.

- Functional Interfaces. A drawing review isn’t complete without some verification that the part works well within an assembly. This section adds check list items to ensure you can be confident about final assembly functionality.

- Design for manufacturability. Every manufacturing process has different drawing requirements. This section introduces some of the common checks in CNC machining, sheet metal fabrication, and injection molding. It’s a great starting place to build your own DFM check list items.

Get a copy of the checklist!

We’ve created a few different formats of the the part drawing checklist so you can duplicate or download your own copy easily in the format you prefer.

Or read it here first

Individual mistakes are unavoidable → You need a review process

If you want to put in place a review process that eliminates mistakes, shortens development cycles, and guarantees you'll design and build better hardware, check out our Ultimate Guide to Drawing Reviews. You’ll learn how to institute a frictionless drawing review process no matter what stage of product development you are working through.

Even the best engineers make mistakes on drawings. It’s unavoidable. Five Flute was built to power your 2D drawing review workflow, whether you are a team of 2 or 200. You can fly through drawing reviews in less than half the time, and with fewer mistakes. If that sounds helpful, you can sign up for a short demo to learn more.

Stop printing drawings, Slacking screenshots or emailing PDFs - try Five Flute today. Cheers!